That is an article that I will reread and reread again. Professional Guide To Wheel Building 5th Edition Pdf. I've installed about 120 out of approximately 145 switch motors and these manual controls have me intrigued.

Put a magnet on each Pole - it instantly stays stuck!! Thats an interesting idea. Because it also removes the need for a locking pin.

You could assemble the whole thing. Figure out where the throw needs to begin and end.

And glue magnets in those spots. You would eliminate the need for most of the fussy work. It would have a nice positive feel to the motion. You combine that with the dowel idea and you have a very nice easy to move throw. You could line multiple throws very quickly. I like the magnet idea a lot! Well it seems no one really understands what I tried to explain so, I took 10 min after I got home and made a controller.

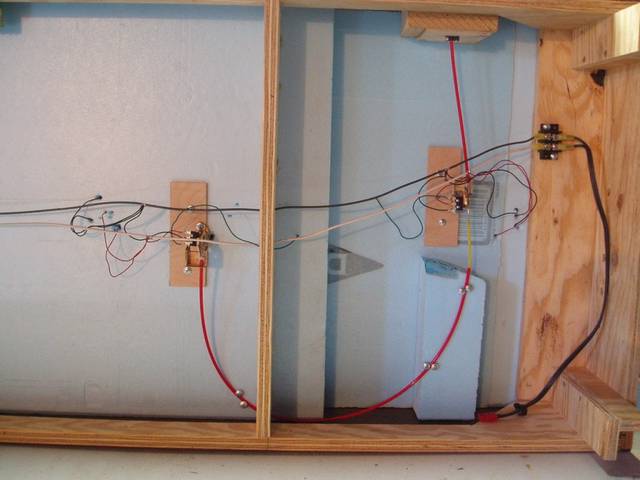

It took me longer to re-size the photos to fit the page so I hope these will show you what I meant. On the front of the fascia panel I have written Lock pin 'L' and 'R'. These are nails1-3/8 inches long 4d box nails that I hammered through the fascia until they were flush with the back & then cut them off to leave 1/4 inch of the nail sticking out of the fascia front to use as a stop keeper for the lever.

I measured the points where these stops were placed after everything else was finished so i knew where the lever needed to be in order to keep the switch handle in the proper positions. In order to operate you pull the switch straight out 1/4 inch and turn it to the left or right and once past the stops on the outside the stops on the inside stop the the turning ability of the switch handle and you simply press the handle in once past the stops on the outside fascia. Where at the same time the stops on the inside of the fascia are also stopping the switch from moving any farther. When your ready to change the switch points you pull the lever and the main dowel out 1/4 inch and turn the handle to just past the opposite stop and press the main dowel back in against the fascia. Those illustrations are perfect - we're all sort of on the same page!! And you added a GREAT new idea to the mix I didn't even thing about - COUNTERWEIGHTS ON THE SHAFT!!!

See, some of us are trying to put Power routing and signal lighting all into the siwtch mechanism. We would do this by connecting the power through the metal stop pins so that hte whole thing operates like a big switch.

But this is problematic because a static friction throw might spring open just enough to reduce or remove all electrical continuity. So then my idea is to attach magnets to the two metal stops so that the metal is magnetized and thus it magnetically snaps like a switch. I like how your module works, but I know my local club members would all point out that this would be a bear to rub agains, as would happen and happen alot. But your illustration brought a new part to fruitation.

If we mount the dialomatic low enough, we can put a leverarm on the axle with a weight on the end. Virtualbox Activate Windows 7. Throw to the left, and the weight pushes down on the left side of the lever, snapping the stop on the axle to the right stop on the base.

And there is a way to solve the amount of throw needed to engage the switch, because when I built my version a little over a year ago it took three revolutions to completely throw the switch: use a spool on the end of the axle to expand the axle diameter. The biggest problem left is the stress test of how long the cable will last. I used brass wire and it was broken in a very short amount of time!! • or to post comments. I think Charlie has the best Idea of using multi strand fishing line. I have some Multi strand 250 pound test fishing line over 30 years old that looks exactly like the line Charlie uses in his photos and have been using the same 1000 foot roll which is now about 400 foot long to tie up news paper. You can't break it with your bare hands you have to use a sharp knife to cut it.

Copper or brass wire will loose tinsel strength fast rolling and unrolling it becoming very brittle and break in almost no time. Yep that it did!!! Less then a day! The only problem I have with fishing line is how it rots after time - at least, with trout test line, the part that goes int eh water a lot can be pulled right apart after one season and must be pulled off at the beginning of the next season.